India’s Electric Vehicle Market: A Look Back at 2023 Get...

Read MoreVineet Dravid

Founder & CEO oorja

oorja’s hybrid-based simulations allow you to design and evaluate battery packs under various temperatures and operating scenarios

As battery-driven electric vehicles come into the mainstream, predicting battery longevity becomes critical for various reasons. The battery pack is typically the single most expensive component of an EV, currently ranging anywhere between 30% to 40% of the total cost. In order to instil customer confidence, it is imperative that manufacturers provide lengthy warranties for the battery packs, ranging in some cases up to ten years.

However, this presents a real challenge for EV manufacturers, especially since predicting battery life is complicated by several factors. The traditional physics-based modelling approach is not effective in accurate battery life prediction since it depends on over twenty physical and design parameters, which are unknown. Also, battery optimization covers a large space of materials, such as electrodes, electrolytes separators etc. This makes it difficult to get quick feedback on the performance during the design and development process. Maneuvering this large parameter space often leads to complexity and inaccuracies creeping into the modelling.

While machine learning helps address some of these issues, it comes with its own set of challenges. Pure machine learning needs voluminous amounts of data and is still prone to overfitting for highly nonlinear physical systems.

In the past few years, there has been considerable interest in blending these two approaches – physics-based with machine learning – to leverage their respective strengths and come up with simpler and faster, yet accurate models. There are several ways in which hybrid models, a combination of physics-based and machine learning, can be constructed to enable accurate prediction, and this has been a topic of research for the past decade.

The key advantage of using this approach is that the “shortcomings” of the physics based models are overcome by the experimental data that the ML model uses. Similarly, since the approach starts with mathematical models, the need for voluminous data is reduced

At oorja, we have developed an easy-to-use interface to predict capacity fade in batteries while minimizing the amount of data needed to perform such an analysis. Our goal is to simplify the entire design process and enable quick computation of capacity fade and battery degradation, without the need to gain expertise in modelling techniques.

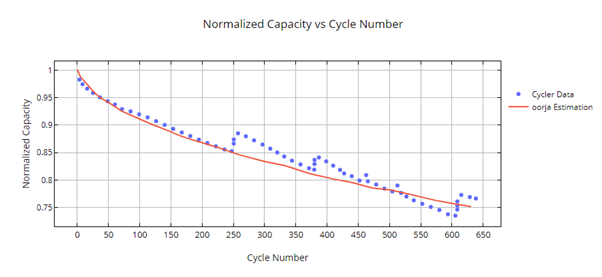

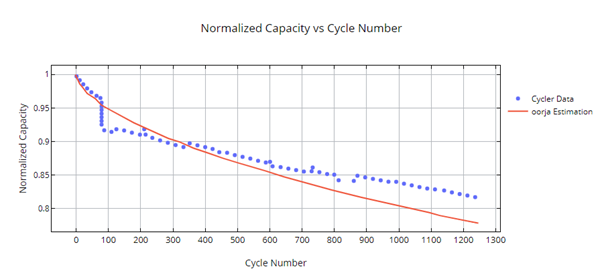

Below are some results from our software, where a varying number of cycles of data was taken for the training, and predictions were performed for capacity fade over the number of cycles. The objective was to test how the predictions fare even with minimal data used for parameter extraction. The validated results show an accuracy of over 90% with experimental data.

All the experimental data used for validation comes from batteryarchive.org[1] who have compiled data for various cell chemistries and charge and discharge rates over several years. Figure 1 shows a validation case where the first 100 cycles were used for parameter training and Figure 2 shows a case where only the first 10 cycles were used for training.

As can be seen, adding more cycles can increase the accuracy of predictions. However, even with lesser number of cycles, good qualitative trends can still be obtained, thus giving valuable insights quickly at the beginning of the design cycle.

If you are interested to try oorja for capacity fade predictions, contact us at info@oorja.energy for more details.

Latest Blog Posts

Hybrid Modeling: Bridging Physics and Machine Learning

Hybrid Modeling: Bridging Physics and Machine Learning Get Started Contact...

Read MoreAccelerated Degradation Predictions using Hybrid (Physics+ML) Simulations

Accelerated Degradation Predictions using Hybrid (Physics+ML) Simulations Get Started Contact...

Read More