Battery Modeling and the Goldilocks Zone Get Started Contact Us...

Read MoreVineet Dravid

Founder, CEO oorja

Predicting anisotropic thermophysical properties of batteries using oorja

Lithium-ion batteries today power the lives of millions of people each day. From laptops and cell phones to electric cars and scooters, this energy storage technology is growing in popularity due to its light weight, high energy density, and ability to recharge. In our recent blogs, we spoke about how crucial temperature is to battery performance, safety and life. USABC requirements on li-ion battery thermal management state that a battery pack should operate at temperatures between -30 ºC to 52 ºC and also that pack temperature uniformity should be less than 3 ºC. Hence, it is critical to ensure that battery systems are cooled efficiently and uniformly.

Conventional challenges in predictive modeling of batteries

While there are several available approaches to perform predictive modeling of batteries, a major challenge is predicting thermal conductivity of the cell accurately. Battery cells are complex engineered products. Their thermal conductivity is not isotropic in nature. A single cell usually consists of an anode and a cathode stack with an electrically insulating porous separator between them. Each of these components has its own conductivity.

Both anodes and cathodes are porous materials with varying particle sizes, depending on the exact chemical compositions, applications and manufacturer. Further, the anode or cathode stack has a current collector which is coated on both sides with a porous mixture of the active material and binder. The electrodes are then immersed in a liquid electrolyte with a different conductivity.

The thermal conductivity of each of these component layers of a cell can differ by several orders of magnitude. For instance, porous anodes have been reported to have a conductivity range of 0.26 – 3.5 Wm-1K-1 depending on the electrolyte in pore spaces, while cathodes have a range of 0.13 – 2.49 Wm-1K-1 for the same conditions. Similarly, separators can have a conductivity of 0.1 – 0.4 Wm-1K-1.

This makes estimating the anisotropic conductivity of the cell extremely challenging. However, it is imperative to get the anisotropic conductivity values to get accurate temperature estimates, which in turn ensures a robust battery pack design.

Quickly analyze and estimate accurate anisotropic parameters with oorja

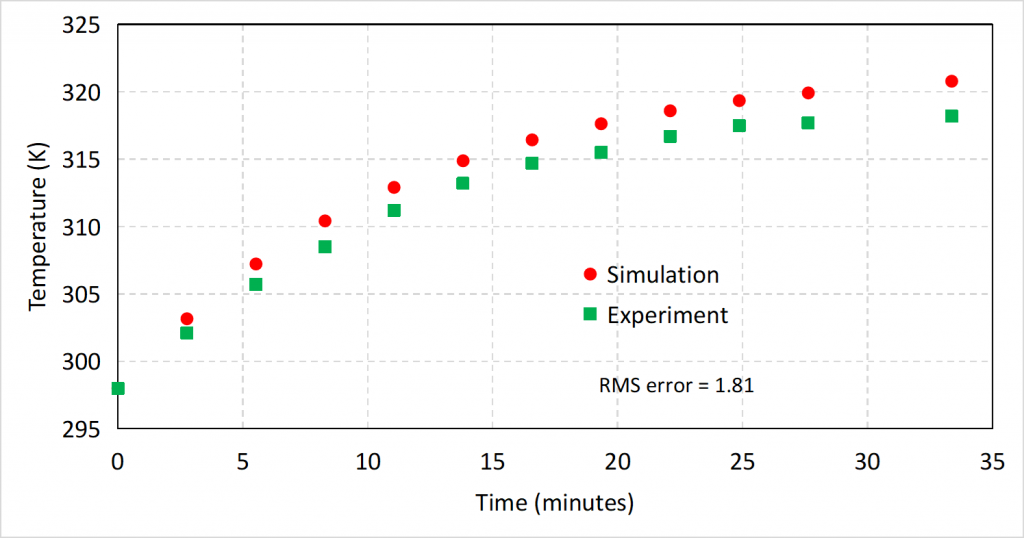

With oorja’s hybrid physics-based solutions, you can input easily available experimental data in its user friendly application to quickly estimate the anisotropic parameter values. The figure below demonstrates this.

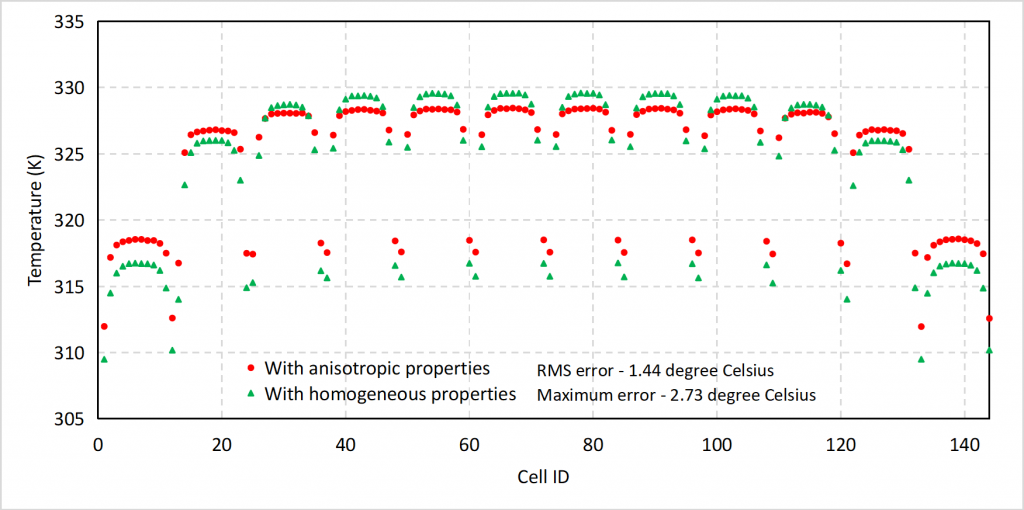

Folks we talked to said they were not sure how significant was the impact of non homogenous thermal properties on cylindrical cells, which are typically smaller than pouch and prismatic cells. We ran experiments on a 21700 cell with two parameters. The first was with equivalent thermal conductivity, the usual norm when doing predictive modelling. In addition, we also used the radial and axial conductivity extracted using experimental data. We found a 5oC difference between the two results, as seen in Fig 2.

This outlines the importance of using anisotropic conductivity in thermal management modeling Predicting accurate anisotropic conductivity in thermal management modeling of batteries can help ensure that your battery systems are cooled efficiently and uniformly.

Write to us at prajakta.sabnis@oorja.energy and explore how oorja can help you with accurate range predictions. Alternately, visit https://oorja.energy to book a demo.

Latest Blog Posts

India’s Electric Vehicle Market: A Look Back at 2023

India’s Electric Vehicle Market: A Look Back at 2023 Get...

Read MoreHybrid Modeling: Bridging Physics and Machine Learning

Hybrid Modeling: Bridging Physics and Machine Learning Get Started Contact...

Read More