Battery Modeling and the Goldilocks Zone Get Started Contact Us...

Read MoreVineet Dravid

Founder & CEO oorja

Thermal Runaway Mitigation using oorja

Introduction

Ensuring battery pack safety is critical to the success of EV adoption. A recent study conducted in India found that 45% of the respondents chose not to purchase EVs because of fears of battery fires. It is well known that thermal runaway is the primary cause of battery fires. Designing packs to mitigate the risk of thermal runaway (TR) is challenging since runaway occurs due to manufacturing defects either at the cell manufacturing or pack assembly level. This is a probabilistic event which cannot be captured using physics-based modeling.

Further, modeling the onset of a thermal runaway at the cell level is also impossible using pure physics-based modeling since capturing the extremely rapid reactions leading to thermal runaway cannot be done using physics-based models.

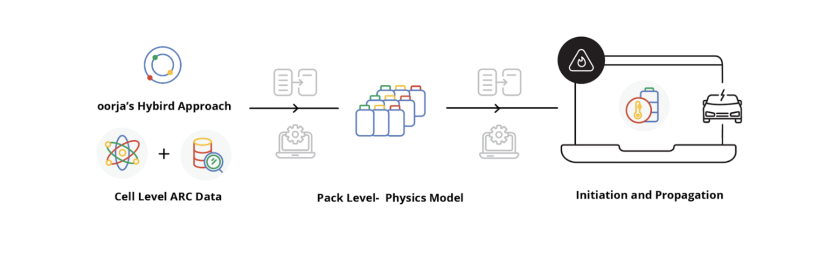

oorja’s hybrid approach enables battery pack designers to generate several what-if scenarios at the concept design stage quickly and ensure that irrespective of the location of the rogue cell or cells in the pack, thermal runaway at the pack level can be mitigated. oorja’s cloud-based application can be used to quickly assess the impact of cell placement, thermal pads, or PCMs— and a pack where the risk of explosion is minimised can be designed, greatly reducing the need for experimentation.

Approach

oorja’s hybrid approach uses a combination of cell-level ARC (accelerated rate calorimetry) data, extracts information from it and constructs a pack-level physics model which accurately captures thermal runaway initiation in each cell of the pack. The impact of venting, cell spacing, and different active and cooling mechanisms is built into oorja’s HEAT application.

Analysis

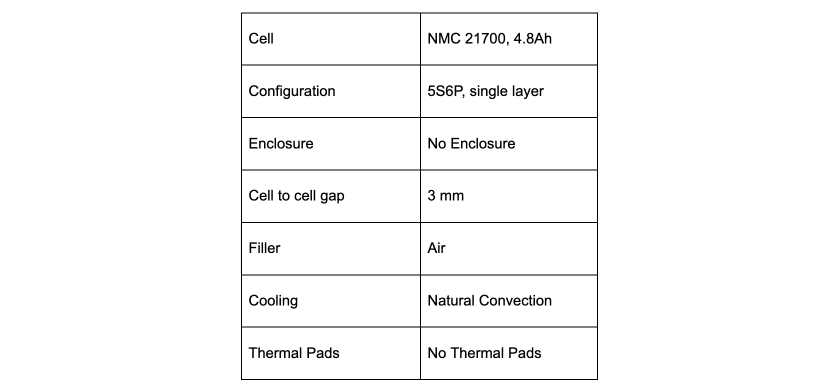

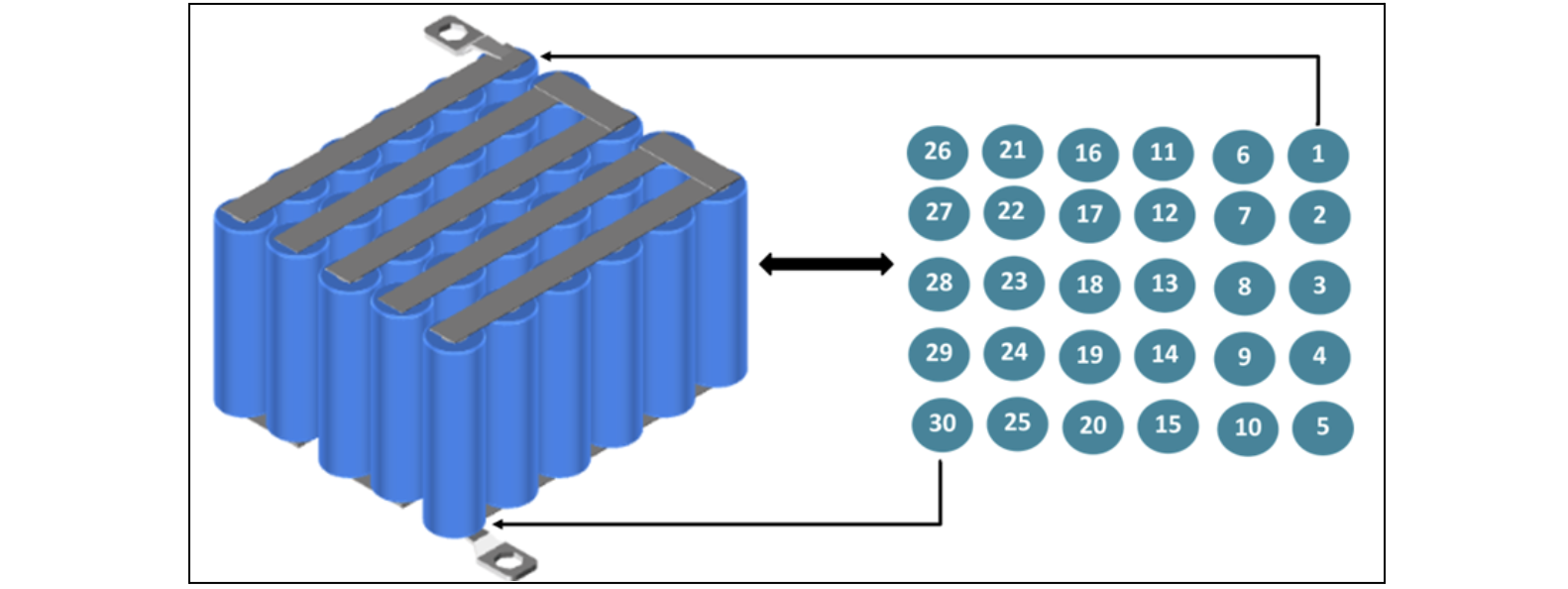

We consider here a case of a 5S 6P battery pack to ensure that irrespective of the rogue cell location in the pack, thermal runaway in the rouge cell will not lead to rapid propagation of thermal runaway throughout the pack. This will ensure explosion prevention.

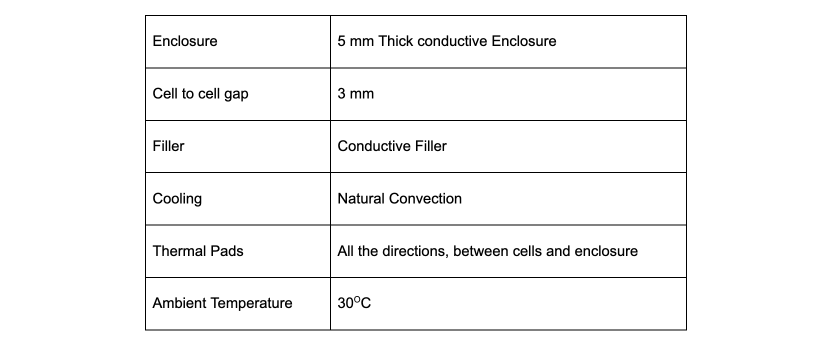

We start by looking at the pack with the following specifications:

Pack Design

Fig.1: Pack Structure.

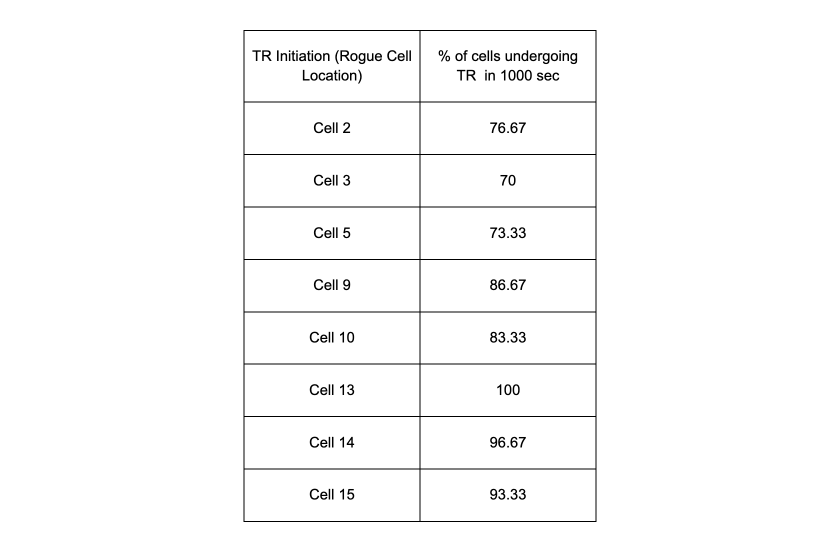

And see that if cell 13 undergoes thermal runaway, it leads to rapid propagation of TR in all the cells in the pack. This will lead to a pack explosion due to the excessive heat generated within the pack.

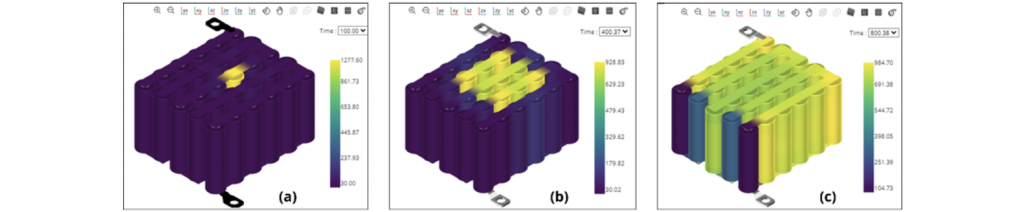

Fig.2: Thermal Runaway Initiation and Propagation from Cell 13. (a) Temperature at 100 sec (b) Temperature at 400 sec (c) Temperature at 800 sec.

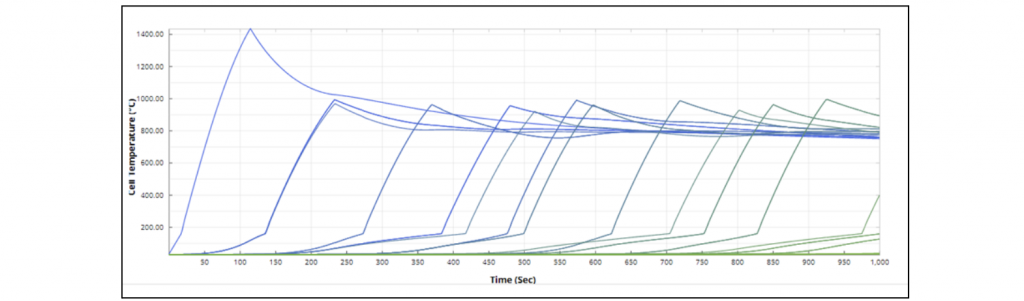

Fig. 3: Thermal Runaway Propagation- all the cells undergo TR.

Fig. 4: TR propagation with different trigger locations.

We now modify the 5S6P pack design, to ensure irrespective of location of the rogue cell, TR does not get propagated.

Modified Pack Design

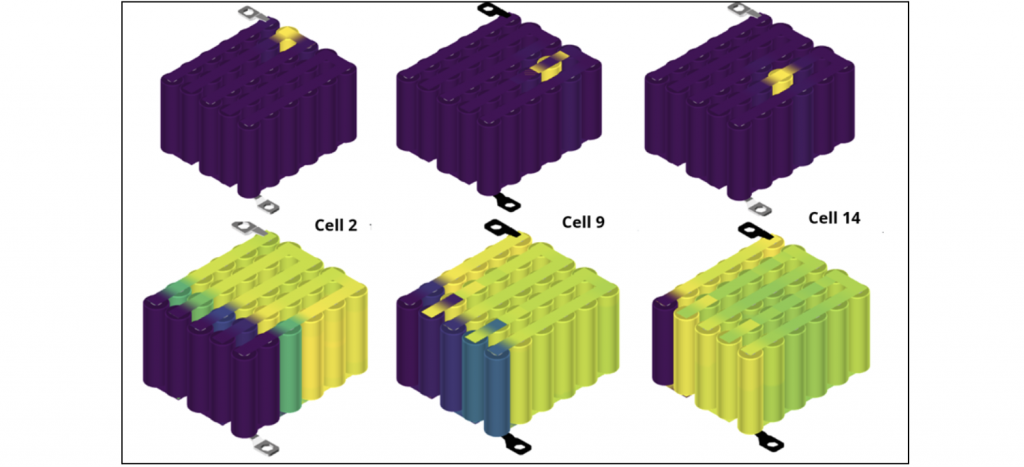

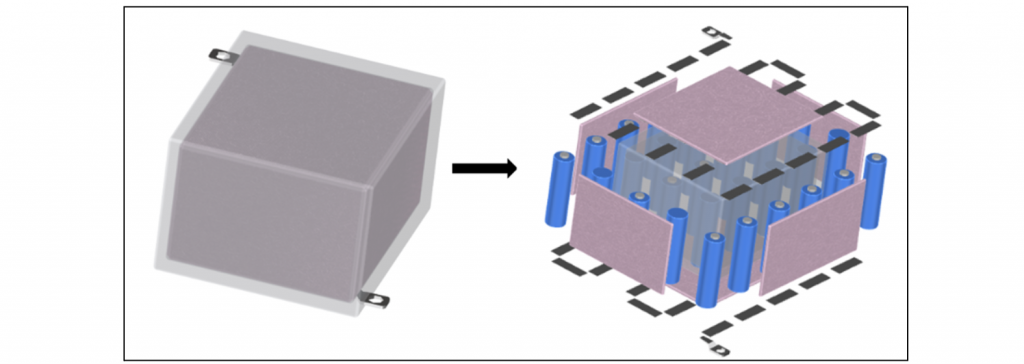

Fig.5: Modified Design: Normal and Blow-up view.

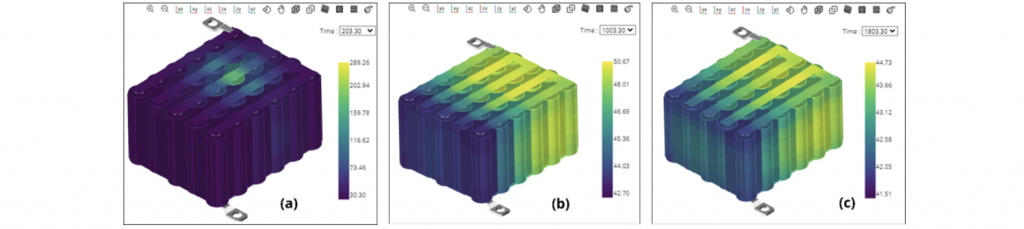

Fig.6: Thermal Runaway Initiation from Cell 13,TR doesn’t get propagated (a) Temperature at 200 sec (b) Temperature at 1000 sec (c) Temperature at 1800 sec.

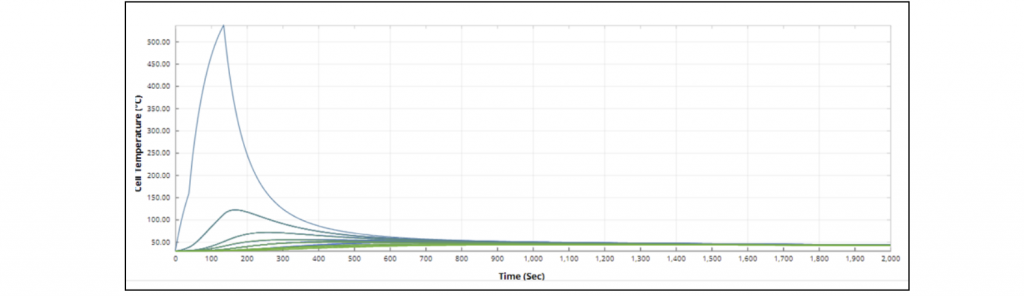

Fig. 7: TR initiation in rogue cell- Pack doesn’t undergo TR.

Validation

oorja’s HEAT application suite has been extensively validated for all aspects of thermal management and thermal runaway. The below figure shows a comparison of oorja’s results with a prismatic pack where thermal runaway was introduced.

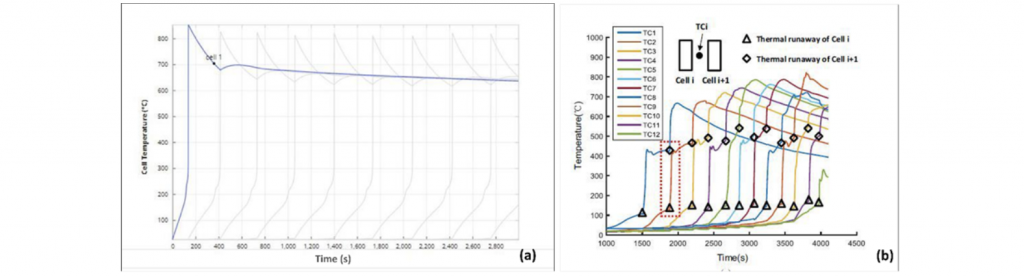

Fig. 8: TR Propagation in 12S1P Module (a) oorja Results (b) Published literature (Ref.1).

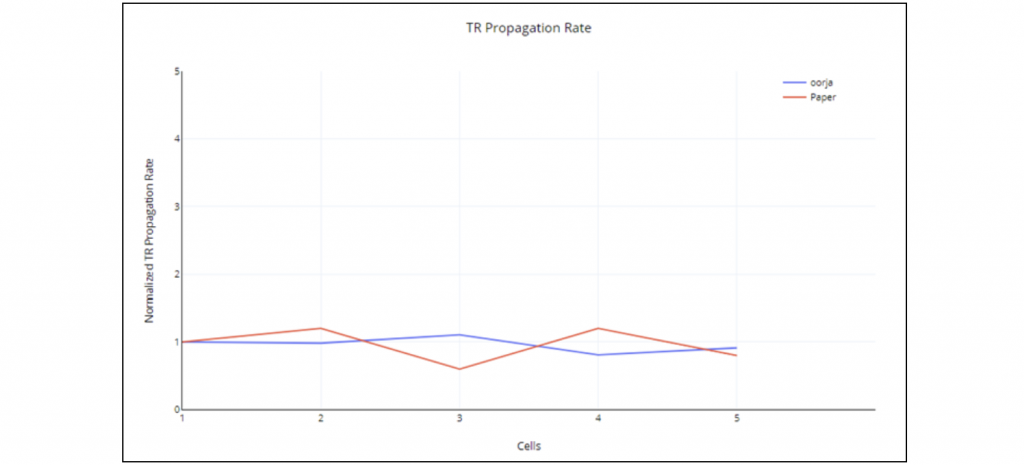

Fig. 9: TR Propagation Rate Comparison.

Thermal Runaway propagation in a 12S1P module is studied. As described in Ref[1], the 12S1P module consists of 37 Ah NMC prismatic cells, with a cell-to-cell gap of 2.7mm. Thermal runaway in the module is triggered by an external heater, with 16kW power. Enclosure material, dimensions, cell dimensions and filler material properties are assumed.

As Fig.8 shows, all the cells in the module undergo thermal runaway. As can be seen in Fig.9, the rate of thermal runaway propagation is qualitatively in good agreement with the experimental data[1].

To explore how you can use oorja to design safe battery packs right the first time, contact us at info@oorja.energy.

References:

- Shang Gao et al, “Experimental Study on Module-to-Module Thermal Runaway-Propagation in a Battery Pack“ 2019 J. Electrochem. Soc. 166 A2065.

Latest Blog Posts

India’s Electric Vehicle Market: A Look Back at 2023

India’s Electric Vehicle Market: A Look Back at 2023 Get...

Read MoreHybrid Modeling: Bridging Physics and Machine Learning

Hybrid Modeling: Bridging Physics and Machine Learning Get Started Contact...

Read More