Battery Modeling and the Goldilocks Zone Get Started Contact Us...

Read MoreVineet Dravid

Founder & CEO oorja

What is HPPC testing and why is it important for battery modelling?

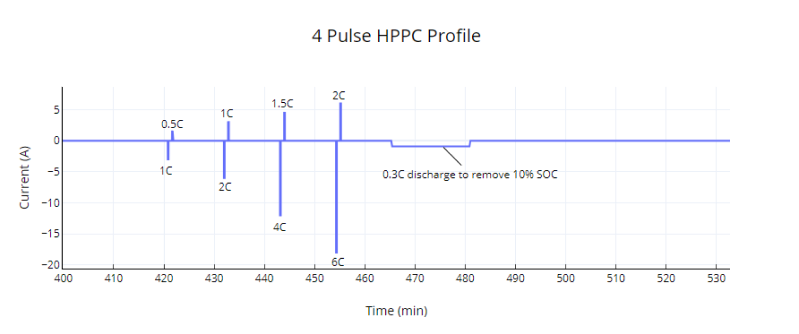

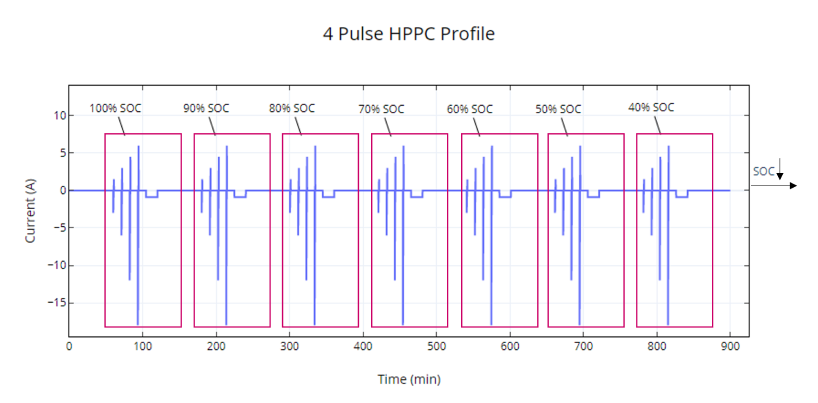

The Hybrid Pulse Power Characterisation (HPPC) test was first proposed by the US DOE as a standardised test to determine the dynamic power capability over the cell’s useable charge and voltage range[1]. The primary objective of the test is to establish, as a function of the depth of discharge (DoD) the Vmin discharge power capability at the end of a 10s discharge current pulse and Vmax regen power capability at the end of a 10s regen current pulse (see Figure 1). This information is then used to extract other performance related information such as available energy and available power.

However, the data collected during HPPC testing can also be used for extracting other information regarding cell performance. Specifically, from the voltage response curves, cell resistance as a function of SOC can be extracted, which can then also be used to evaluate the heat generated in a cell during both charge and discharge. The open circuit voltage (OCV) for various SOCs can also be extracted, as will be highlighted below. Using available HPPC data, mathematical models can be set up which can predict heat generation for various user drive cycles.

Test Procedure

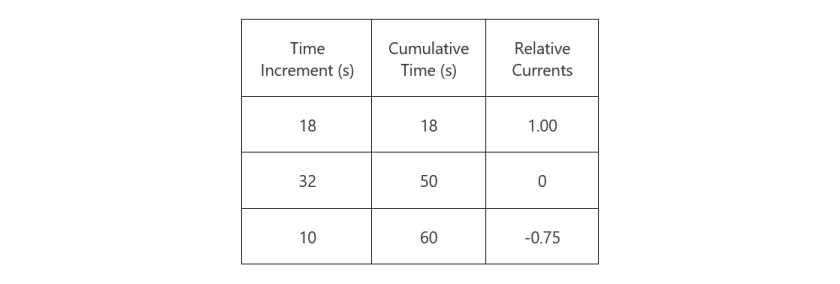

The test begins with a fully charged cell after a one hour rest period. The normal test protocol uses constant current at levels derived from the manufacturer’s maximum rated discharge current. The cell is then subjected to the charge discharge profile discussed above. Table 1 also lists the current profile in each sequence.

Caution should be exercised while designing the experiment that the capacity consumed during any pulse cycle does not exceed 10% of the total capacity of the cell. Each charge discharge sequence is followed by a 60 minute rest period to ensure the cell reaches charge equilibrium. This is followed by a 10% DOD discharge segment at constant current, followed again by a 60 minute rest period. Then, the next HPPC sequence is applied. This entire sequence keeps repeating and the test terminates when the cell reaches 90% DOD (see Figure 2).

The voltages during the rest period are also recorded to establish the cell OCV behaviour. Further, this experimentation can be carried out at different ambient temperatures to enable voltage and heat source prediction as a function of both the SOC and Temperature. Additionally, the current pulses can also be varied at higher C rates to give more insights into cell behaviour during high C charging and discharging.

Interpreting HPPC Data

While interpreting HPPC results it is important to note that the estimates are dependent on the prescribed pulse duration and initial conditions. For instance, the maximum voltage drop due to the discharge current pulse occurs at the end of the pulse. If the discharge current is allowed to extend beyond the stated period of, say 10s, the power capability estimate will decrease because of a lower Vmin. Therefore care has to be taken on how to interpret HPPC data. HPPC testing has proved to be useful because applying short current pulses gives us a window into the physical behaviour inside the cell. For instance short current pulses allow interfacial phenomena to be captured, whereas longer pulse durations ensure the bulk diffusional effects are also accounted for. This gives us a window into the physical phenomena going on in a cell without either extensive experimentation or first principles modelling. Understanding how to setup the experiments, and how to interpret results can help extract valuable information from the experimentation and do efficient predictive analysis. Recent research has investigated the impact of varying pulse duration and rest periods between charge and discharge pulses on the model accuracy. To summarize, apart from the original stated goal of estimating the power capacity of a battery, HPPC data can also give you information on internal impedance and SOC vs OCV. Using this information, mathematical models can be setup to predict voltage and heat generation for any drive cycle, and at different temperatures.

What oorja Does

Our goal at oorja is to allow you to extract the most out of any available experimental data. In oorja, you can input any HPPC data you have, and at the backend, we extract the necessary information to set up the most accurate model possible for the amount of available data. HPPC experimentation is relatively fast and inexpensive, so it should be possible to generate meaningful data in less than a week.

If you don’t have experimental facilities available, feel free to reach out to us. We have tied up with reliable experimentalists who can quickly provide you with relevant data. As a first cut, for cell selection, you can also use our available HPPC database to kickstart your design process.

Latest Blog Posts

India’s Electric Vehicle Market: A Look Back at 2023

India’s Electric Vehicle Market: A Look Back at 2023 Get...

Read MoreHybrid Modeling: Bridging Physics and Machine Learning

Hybrid Modeling: Bridging Physics and Machine Learning Get Started Contact...

Read More